As the process proceeds the. JM-5000 Wet Wire Drawing Lubricant This wiretube drawing compounds oil has been manufactured on the base of Lubricating oils with many EP.

Lubricants For Wire Drawing For Welding Consumables Production

Lubrication in Wire Drawing.

. Applications include bearings chains conveyor chain lubrication conveyors frozen bolts nuts pins pulleys open gears sliding surfaces. Dry wire drawing lubricants are a special type of lubricant which is used to reduce the friction between wires and drawn metal parts. BECHEM Unopol F 635is a drawing lubricant for bare tinned silver-plated and nickel-plated copper wire on single and multi wire machines up to a final diameter of 010 mm in some cases down to 007 mm as well as for enameled wire production.

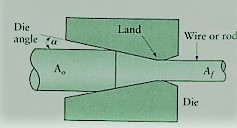

This oil is used in single or multi pass with heavy reduction also use in co2 skin pass. Lubrication in the drawing process is necessary to maintain a good surface finish and long mold life. Pail 55 gal.

Oil dispersions are available in 5 gal. Claim 1 Symbolplacing wet drawing lubricant were added into the water solution and without in the aqueous solution for reinforcing a rubber article steel wire the steel wire which is brass-plated characterized in that wet-drawing Wet wire drawing method. For drawing tube or pipe a lubricant must be able to withstand extreme pressures and significant heat buildup.

Free easy returns on millions of items. In extreme cases the wall fails. WILCO Lubricant Applicators are a wire drawing aid designed to apply more lubricant on the rod or wire surface.

Testing and validating new lubricants is nothing new to the tube and pipe industry. Ad Browse discover thousands of brands. GB-1416213-A chemical patent summary.

Lubricants For Non-Ferrous Wire. In dry drawing the lubricant is in the form of solid powder which is generally a mixture of soap. Blachford manufactures many products for non-ferrous wire applications and often.

Ad Best Deals On thousands of products. BECHEM Unopol F 635 is characterized by high performance good cleaning effects and long emulsion life. ISO 90012015 certified custom manufacturer of wire drawing lubricants including molybdenum disulphide oil dispersions.

NuDraw 212 is a sodium tallowate lubricant used for wire drawing as well as yellow metal forming. Order today with free shipping. There are currently four different types of lubrication methods.

The liquid lubricants can immerse a wire fully in water-miscible neat oil or in the solution synthetic lubricant. WILCO Lubricant Applicators can be used in each die box of multi-draft machines or just in those die boxes. Get the Deals now.

The high-quality lubricants can fulfill your operating needs. There are mainly two kinds of lubrication process that are utilized for wire cold drawing and they are liquid lubricants and soap lubricants. This cold wire-drawing material is produced by applying an aqueous solution obtained by mixing sodium stearate and calcium oxide on the surface of the base material and carrying out the cold wire-drawing working by using the lubricant.

Free shipping on qualified orders. It consists of paraffin waxes or heavy oils which are completely dry and do not flow under pressure. Various types of lubricants are used from soaps oils water-based solutions etc.

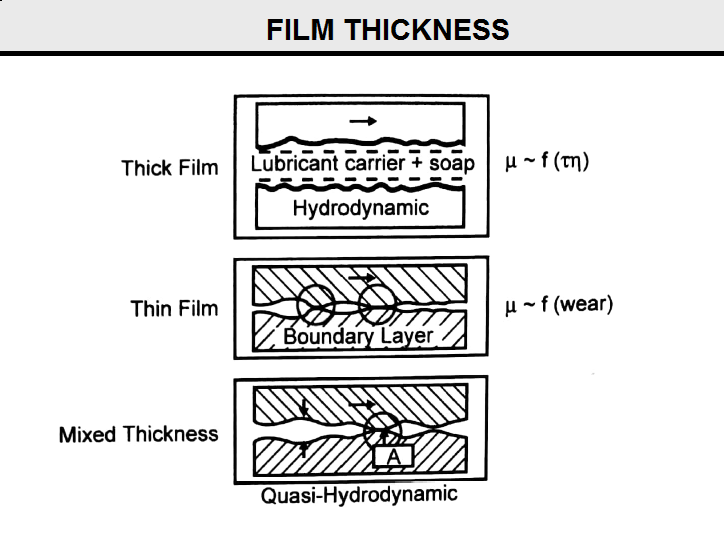

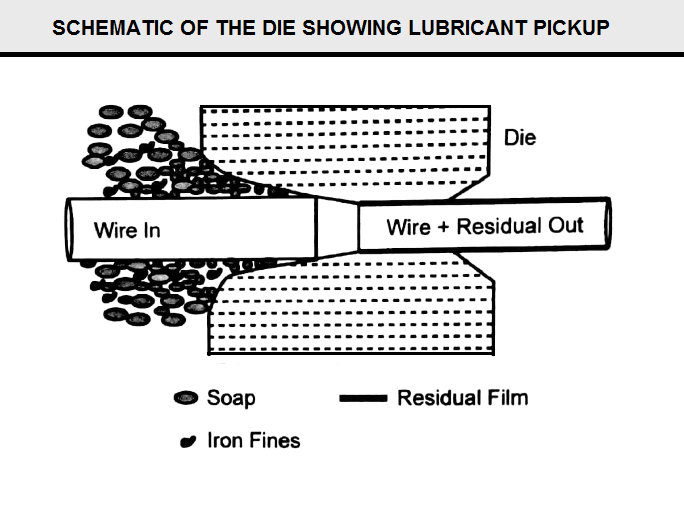

Wet drawn dry drawn metallic paint and ultrasonic vibration. Most wire is drawn using the dry drawing process and even wet called dry drawing process the wire comes in intimate contact with a dry powdered lubricantgenerally a calcium sodium or aluminum stearate which reduces the friction between the rod and the die. More lubricant assures smoother more efficient wire drawing operations.

It gives extra bright finish on drawn products. Read customer reviews find best sellers. The role of wire rope lubricant.

It is designed for high or low speed single hole drawing for all ranges of ferrous and stainless steel stock. It is a water soluble granular powder and does not contain lime sulfur phosphorus or chlorine. Best performance is achieved when using with dry powdered soap lubricants.

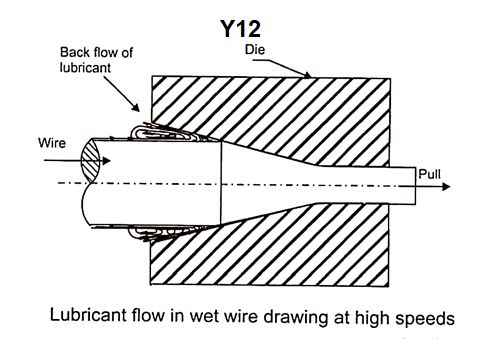

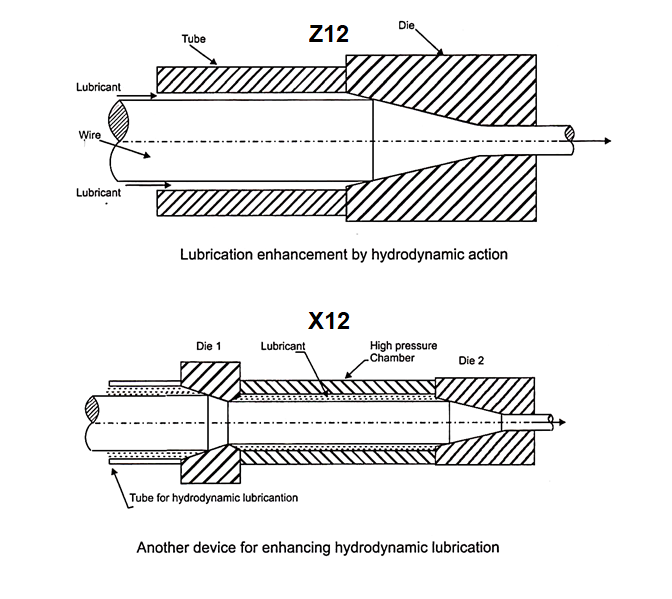

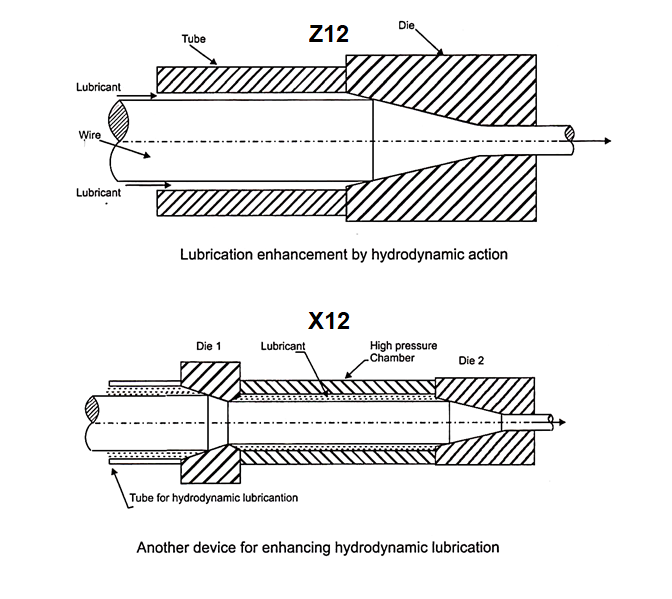

Wire Pre-Coats And Emulsions. Wet drawing is used for obtaining bright surface finish and for using hydrodynamic lubrication devices. This is the key to successful dry drawing and borax or Neoborborax.

Lubricants for Wire Drawing Lubricants For Ferrous Alloy Wire. A lubricant without these characteristics can lead to ID scratches and a draw force that increases rapidly. For more information meet CONDAT lubricant experts at Wire Düsseldorf Hall 10 Stand A52 or contact us on wwwcondatfr or infocondatfr.

Discover amongst this offer the high performance borax-free sodium soap VICAFIL SANTALE 6 and non-reactive surface treatment VICAFIL TS 7113 both in use at top wire drawing manufacturers. Blachford produces a wide variety of world-class high performance wire drawing. Lime As A Lubricant Carrier For Wire Drawing Operation 10152013 243 PM Soaps that are sulphonate types might work as they.

Lubricant for wire drawing.

Copper Wire Drawing Lubricants Springerlink

Calcium Based Dry Wire Drawing Lubricants Powder Grade Bb

Wire Drawing Lubricant व यर ड र इ ग क प उ ड व यर ड र इ ग कम प उ ड त र ड र इ ग कम प उ ट In Andheri East Mumbai Markaz International Id 6473787548

Lubricants For Wire Drawing For Welding Consumables Production

Wire Drawing Lubricants Nutech Company L L C

Lubricants For Wire Drawing For Welding Consumables Production

Lubricants For Wire Drawing For Welding Consumables Production

Wire Drawing Lubricants Wire Drawing Lubricants And Soaps Condat

0 comments

Post a Comment